2023

in 2023, core value of xiamen honglu was changed into “unity, diligence, innovation, efficiency, perseverance”

in the next challenges, we will be more persistent and continue to build a great century-old enterprise.

2022

in 2022, in order to establish the long-term incentive and restraint mechanism, to stabilize and absorb talents, and to mobilize the enthusiasm and creativity of key employees, xiamen honglu actively explored and completed the registration of business license of employee shareholding platform. employee stock ownership plan was successfully implemented.

2021

in 2021, key investment project of xiamen tungsten co., ltd in tungsten and molybdenum deep-processing application fields – phase ii of tianxiang plant of xiamen honglu broke ground. the project construction cycle was 18 months, and was expected to be completed by june 2023. then, it was planned that tungsten wire project for photovoltaics will operate there.

2020

in 2020, xiamen honglu actively responded to xtc’s call of “international advanced manufacturing”, sounding a clarion call of lean renovation.

2019

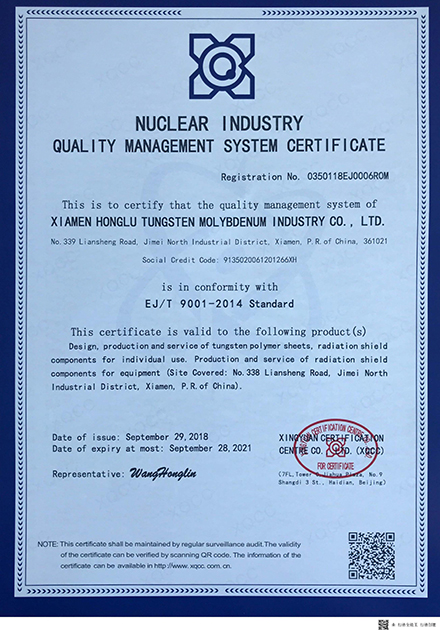

in 2019, xiamen honglu successfully passed the certification of “qualified supplier for china national nuclear corporation”, an important step in entering nuclear power field.

2018

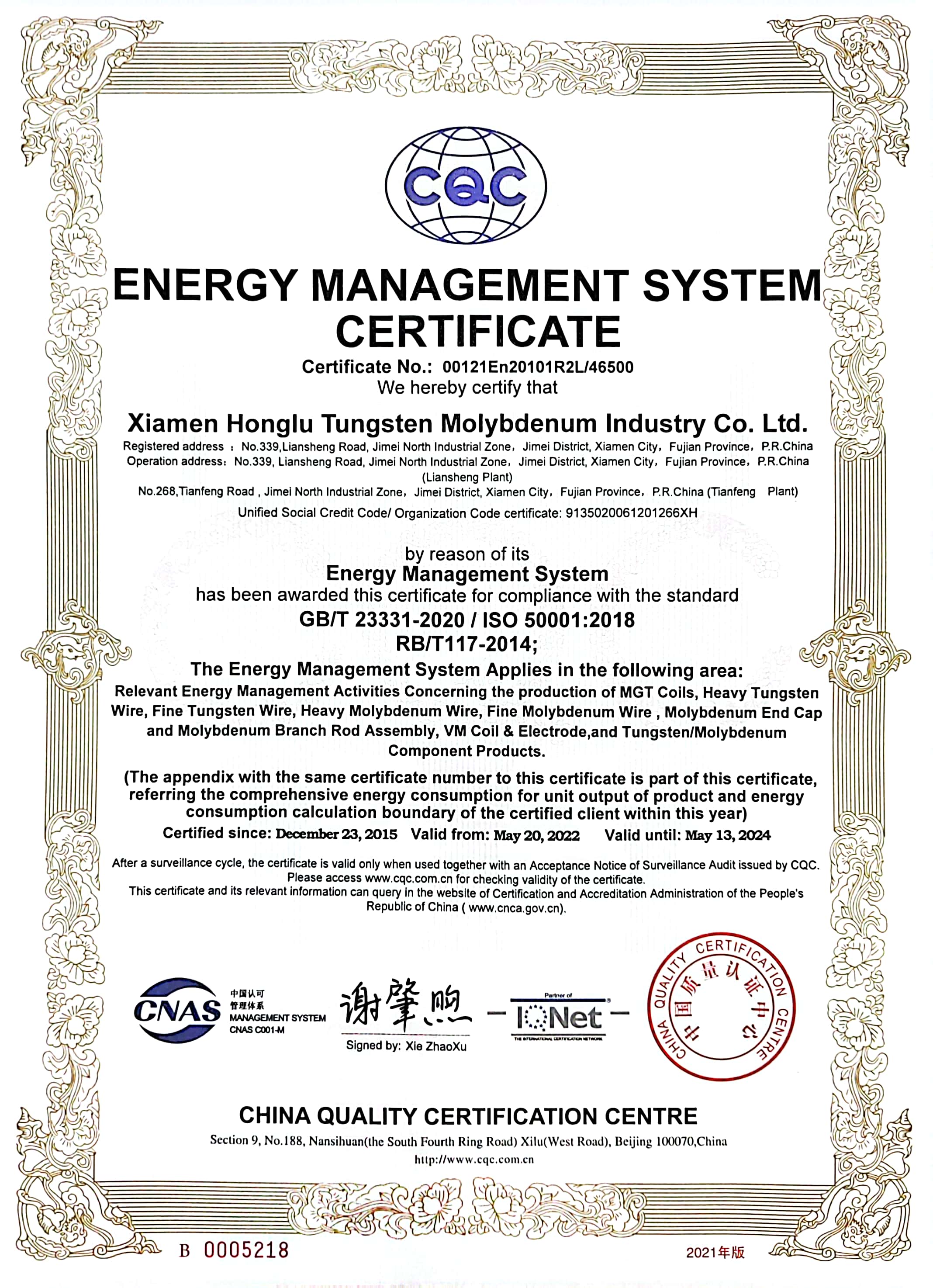

in 2018, xiamen honglu completed the molybdenum wire capacity expansion project, and yearly molybdenum wire production capacity reached 1100 tons.

2017

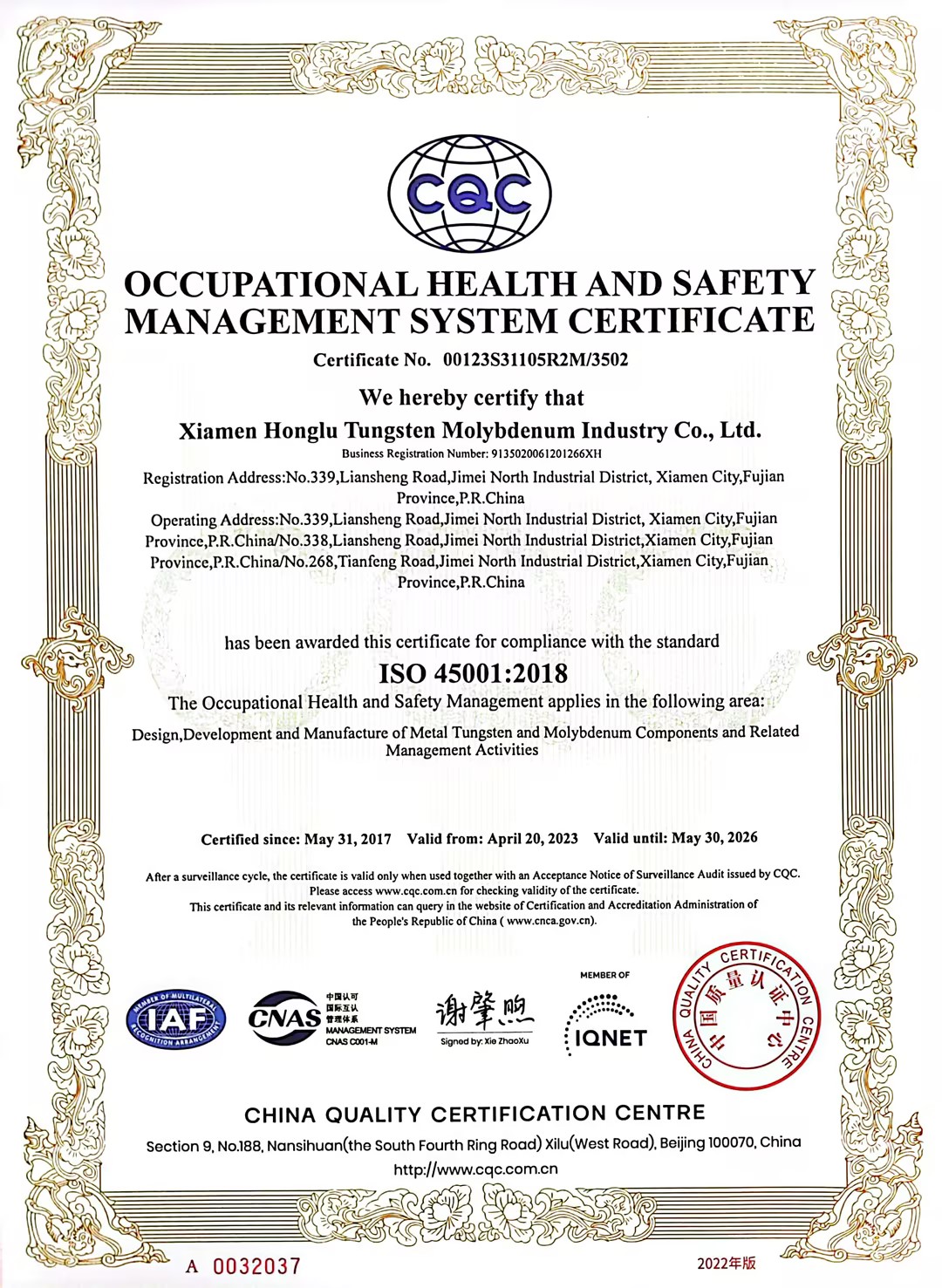

in 2017, xiamen honglu successfully passed the certification of “occupational health and safety management system ohsas 18001”. in the same year, national standard of molybdenum wire gb/t 4182-2017, in which xiamen honglu acted as the first drafting unit responsible for drafting and compiling it, was officially released.

2013

in 2013, components project team was unveiled in tianxiang plant, which kicked off the massive production of tungsten and molybdenum components in xiamen honglu.

2012

in 2012, under the leadership of erp project team of xtc, erp system of xiamen honglu was successfully launched by the end of the year, after one-year efforts.

2010

in 2010, xiamen honglu passed the quality management certification of iso/ts16949:2009, - highest level, top rank, and most authoritative quality management standard in automotive industry. xiamen honglu is also the first of its kind in china.

2009

in 2009, xiamen honglu brought out the company’s vision “to be the international, leading, professional tungsten/molybdenum and other powder metallurgical products supplier”; in the same year, national standard of tungsten wire for lighting and electronic equipment gb/t 23272-2009, in which xiamen honglu acted as the first drafting unit responsible for drafting and compiling it, was officially released.

2008

in 2008, xiamen honglu was awarded “xiamen intellectual property pilot enterprises no.6 batch”, and got the certificate of “new high-tech enterprise ”issued jointly by xiamen science and technology bureau, xiamen finance bureau, xiamen local taxation bureau and state taxation administration, xiamen branch.

2007

in 2007, xiamen honglu passed the certification of iso 14001, and was the first of its kind in china.

2006

in 2006, xiamen tungsten materials engineering and technology research center, which xiamen honglu participated in its setup, was assessed and rated as “national enterprise technology center” by ministry of science and technology and other four ministries and commissions.

2004

at the end of 2004, special tungsten alloy wire production line with yearly capacity of 600 tons was put into production in jimei tianfeng plant. annual capacity of heavy tungsten wire in xiamen honglu reached 1500 tons. meanwhile, applications of products were extended from lighting fields to non-lighting fields.

2003

in 2003, municipal enterprise technology center of xiamen honglu was upgraded to “provincial enterprise technology center”. in the same year, the company signed the agreement with metal research institute of chinese academy of sciences to set up “rare metal processing laboratory”in xiamen honglu. as approved by ministry of personnel, the only “post doctoral programme”in chinese tungsten and molybdenum industry was established in xiamen honglu.

2002

in 2002, enterprise technology center of xiamen honglu was rated as “xiamen municipal enterprise technology center”. self-developed two-roll continuous rolling mill with piece weight of 25kgs was put into production.

1999

in 1999, tungsten wire with honglu brand firstly entered into the supply chain of ge hungary, symbolizing chinese tungsten wire officially went abroad.

1998

in 1998, xiamen honglu successfully developed the first 3kg-tungsten-ingot sintering furnace in china by herself. in the same year, quality system iso9002 was certified by det norske veritas (dnv)and china import and export commodity quality certification center (ccib).

1996

in september, 1996, opening ceremony of jimei liansheng plant, the 2nd phase of xiamen honglu, was held. the company realized the independent production from apt powder to fine wire.

1995

in may, 1995, taegutec. ltd. made capital contribution to xiamen honglu. registered capital and total investment value were increased to usd 7,000,000 and usd 10,000,000 respectively.

1992

in september, 1992, xiamen honglu tungsten molybdenum industry co., ltd was established with registered capital of cny 5,600,000 and total investment value of cny 8,000,000, and was located in 11f,huli dongfang industrial center (currently, huli dongfang commercial plaza).

86-592-6298216

86-592-6298216