![]() 2020-12-14 15:05:20

2020-12-14 15:05:20

today, metal additive manufacturing uses many different processes.

processes can be classified by the way the energy is sourced or the way the materials are joined, such as the use of adhesives, lasers, heated nozzles, etc. the process by which materials are processed, such as plastics, metals or ceramics, can also be classified. the raw material state, most commonly solid (powder, wire or flake) or liquid, also has different processing techniques.

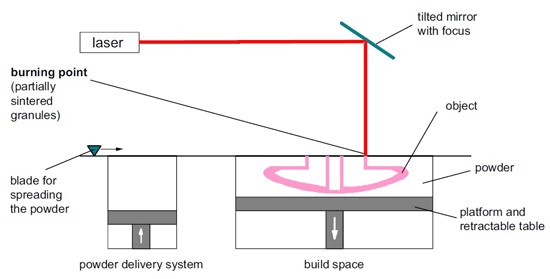

powder bed system

inconel 718 made with micro turbines, turbines

almost all am-based powder bed systems use a powder deposition process, which spreads a powder layer onto a substrate and powder container by coating. typically, these layers have a thickness of 20 to 100 μm. after the powder layer is spread, the 2d slices are glued together, also called 3d printing, or melted using an energy beam applied to the powder bed. in the second case, the energy source is usually a high-power laser, and the latest systems can use two or more lasers with different powers in an inert gas atmosphere.

direct powder processing systems are known as laser melting processes and are commercialized using many names such as selective laser melting (slm), laser melting, and direct metal laser burning (dmls). the only exception to this process is the electron beam melting (ebm) process, which uses an electron beam under full vacuum.

the process is repeated sheet by sheet and layer by layer until the last layer is melted and finished. it is then removed from the powder bed and post-processed as required.

schematic of the selective laser melting (slm) powder bed process (source vdi 3404)

today, metal powder bed fusion machines are available from concept laser gmbh, eos gmbh, realizer gmbh, renishaw and slm solutions gmbh in europe. these companies offer a variety of systems based on similar selective laser melting and use different names for their processes. us-based 3d-systems also offers systems based on selective laser melting. the correct machine selection depends on the requirements of the end user, with the type of laser unit, powder handling and molding cavity being the main considerations. the arcam q20 uses an electron beam to melt metal powder (courtesy arcam ab). sweden's arcam ab manufactures powder bed melting systems that use an electron beam as the energy source for the melting process. the japanese company matsuura offers a hybrid system that combines powder bed fusion and cnc milling. another system that uses a powder bed is the hoganas digital metal craft. developed by fucbic, the system uses precision inkjet technology to deposit special "inks" on a 45-micron layer of metal powder. apply a 45 micron powder layer and repeat this step until the part is complete. the part is then sintered to final size and strength. one of the advantages of this system is that it can be produced at room temperature without partial melting caused by laser or electron beam processes. in principle, there is also no need for a support structure during manufacture, since it is supported by the powder bed.

the arcam q20 uses an electron beam to melt metal powder (courtesy arcam ab)

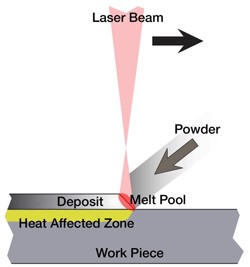

powder feeding system

although the powder feeding system uses the same raw material, the way the material is added layer by layer is significantly different. the powder flows through the nozzle and is melted by a beam of light on the surface of the treated part.

schematic diagram of the laser cladding process (courtesy sulzer ltd)

powder feeding systems are also known as laser cladding, directed energy deposition and laser metal deposition. the process is highly precise and automatically deposits layers of material from 0.1 mm to a few centimeters thick. the method is characterized by the bonding of the cladding material to the base material during sintering and the absence of undercuts. the difference from other welding techniques is that the low heat input penetrates the substrate.

the development of this technology is the laser engineered mesh shaping (lens) powder delivery system used by optomec. this method allows material to be added to existing parts, which means it can be used to repair damaged metal parts such as chipped turbine blades and injection mold inserts, providing a high level of flexibility when clamping parts and coating "materials" higher flexibility.

companies offering the same principle are: beam in france, trumpf in germany and sciaky in the us. dmg mori offers an interesting approach to hybrid systems. the combination of the laser cladding principle with a 5-axis milling system opens up new fields of application for many industrial sectors.